Cold-drawn Precision Seamless Tubes

EN10305-1, EN10305-4, ASTM A519, DIN2391, JIS G3445, GOST8734, ISO3074

Cold drawn and cold rolled precision seamless steel tubes.

Standard and material:

- ASTM A519 (GR.1010, 1020, 1035, 1045, 4130, 4140) Seamless carbon and alloy steel mechanical tubes

- EN10305-1 (E215, E235, E335) seamless cold drawn tubes

- EN10305-4 (E215, E235, E335) seamless cold drawn tubes for hydraulic and pneumatic power systems

- JIS G3445 (STKM 11A, STKM 12A/12B/12C, STKM 13A/13B/13C) carbon steel tubes for machine structural

- DIN2391 (ST35.8, ST37.2, ST52) seamless precision steel tubes

- ISO3074 steel tubes for automotive purposes specification

- GOST8734 seamless cold deformed steel tubes

Size Range:

- Out diameter: 3.6mm-220mm

- Wall thickness: 0.5mm-20mm

- Length: 10m max

Delivery Conditions

The tubes shall be manufactured from hot finished seamless tubes by cold drawing or other suitable processes. The tubes shall be supplied in one of the delivery conditions as follows:

Click to download the details of Cold-drawn Precision Seamless Tubes.

| Designation | Symbol | Description |

| Cold drawn/hard | +C | No heat treatment after the final cold drawing process |

| Cold drawn/soft | +LC | After the final heat treatment there is a suitable drawing pass |

| Cold drawn and stress relieved | +SR | After the final cold drawing process there is a stress relief heat treatment in a controlled atmosphere |

| Annealed | +A | After the final cold drawing process the tubes are annealed in a controlled atmosphere |

| Normalized | +N | After the final cold drawing operation, the tubes are normalized in a controlled atmosphere |

Application

- Automobile shock absorber cylinder

- Dust cover tubes

- Refrigeration gas reservoir tubes

- Motor outer shell

- Motorcycle front fork

- Automobile steering shaft

- Automobile shock absorber reservoir

- Other precision application

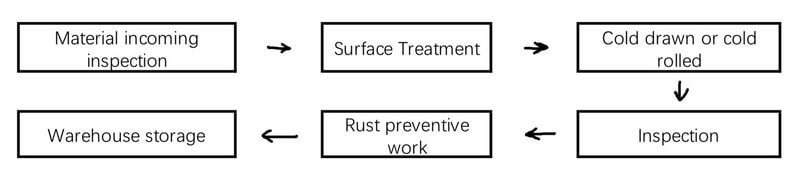

Production process:

production process

Inspection Test

- Universal Material Tester for Tensile strength, Yield strength, Elongation, flattening, cold bending and Flaring test

- Hardness Tester for HRB and HRC inspection

- Roughness tester for Inspection for Roughness, including Ra, Ry, Rz, Rmax

- Chemical Test

- Metallurgical Microscope test

- Straightness Testing

- Eddy current testing

Quality Certification:

- ISO9000

- ISO/TS 16949

Note:

- Mill test certificates will be issued according to EN10204

- The tubes Shall be Seamless cold drawn or cold rolled.

Protection and Packing:

- Packed in wooden box or bundles protected with plastic paper, and suitably protected for sea-worthily delivery or as requested.

- The tubes shall be delivered with a temporary corrosion protection. The type of protection shall be at the discretion of the manufacturer

Production Capacity

- Cold drawn and Cold rolled precision seamless tubes about 30000tons per year

- Precision ERW tubes about 50000tons per year

- Welded structural tubes about 20000tons per year

- Cold drawn welded precision tubes about 30000ton per year

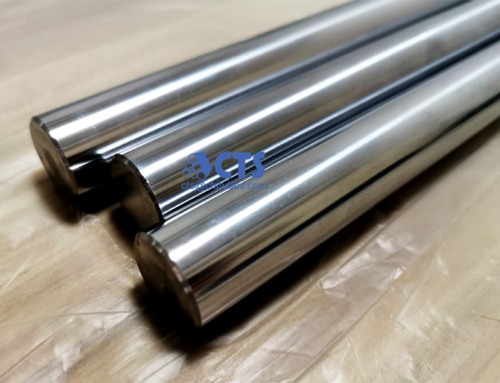

Photos

DIN2391 ST35 cold drawn seamless tubes

cold rolled precision seamless tubes

Get in Touch

If you are interested in our products or service, please contact us now.

Tel.: +86 185 5109 0083 | E-mail: [email protected]